MC 110i EVO2

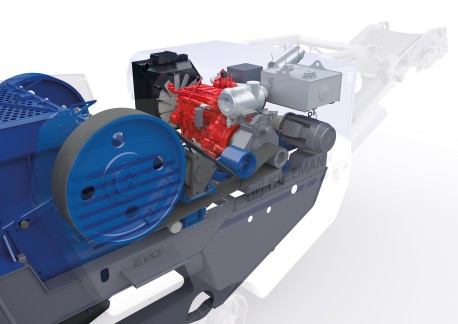

D-DRIVE (Diesel-direct)

990 mm x 620 mm x 370 mm

400

t/h

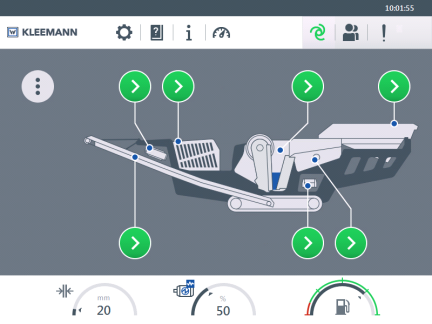

The jaw crusher MOBICAT MC 110 EVO2 is used for pre-crushing of almost all natural stone and for recycling. Compact dimensions, efficient prescreening, simple operation via SPECTIVE as well as impressive production output characterise the efficient key player.

Show more Highlights

Diverse applications, simple transportation, short set-up times, high machine availability: the mobile jaw crusher MOBICAT EVO2.

Feeding unit

Prescreen

CFS

Crusher unit

Unblocking system

Control and overload system

Drive

Control system

Accessibility & Safety

Transport

SPECTIVE CONNECT

Technical specifications

- Max. feed size

- Feeding height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 990 mm x 620 mm x 370 mm

- Feeding height

- 3’910 mm

- Feed height with extension

- 4’280 mm

- Feed capacity up to approx.

- 400 t/h

- Hopper width

- 2’070 mm

- Hopper width with extension

- 2’780 mm

- Hopper length

- 3’370 mm

- Hopper length with extension

- 3’510 mm

- Hopper volume

- 4.4 m³

- Hopper volume with extension

- 7.5 m³

- Width x length

-

- Width x length

- 1,000 mm x 2,600 mm

- Width x length

- Model

-

- Width x length

- 1,000 mm x 1,830 mm

- Model

- Double-deck heavy-piece screen

- Discharge height

- Discharge height, extended

- Width

- Length

- Length, extended

-

- Discharge height

- 2’050 mm

- Discharge height, extended

- 2’940 mm

- Width

- 500 mm

- Length

- 2’700 mm

- Length, extended

- 5’000 mm

- Crusher drive type

- Crusher inlet (W x D)

- Crusher weight (approx.)

- Crushing power

- Single toggle jaw crusher model

- Gap setting

- Adjustment range of gap width

-

- Crusher drive type

- Direct

- Crusher inlet (W x D)

- 1,100 mm x 700 mm

- Crusher weight (approx.)

- 17’000 kg

- Crushing power

- 160 kW

- Single toggle jaw crusher model

- STR110-070

- Gap setting

- Fully hydraulic

- Adjustment range of gap width

- 30 mm - 180 mm

- Crushing capacity CSS = 100 mm up to approx.

- Crushing capacity CSS = 60 mm up to approx.

-

- Crushing capacity CSS = 100 mm up to approx.

- 210 t/h

- Crushing capacity CSS = 60 mm up to approx.

- 130 t/h

- Discharge height approx.

- Discharge height, extended approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 3’140 mm

- Discharge height, extended approx.

- 3’750 mm

- Width

- 1’000 mm

- Length

- 9’500 mm

- Length, extended

- 11’000 mm

- Drive concept

- Generator

- Power pack manufacturer

- Power supply unit output

- Rated speed

-

- Drive concept

- D-DRIVE (Diesel-direct)

- Generator

- 88 kVA

- Power pack manufacturer

- Scania

- Power supply unit output

- 240 kW - 248 kW

- Rated speed

- 1’500 U/min

- Transport height approx. (default value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

-

- Transport height approx. (default value)

- 3’400 mm

- Transport length approx.

- 15’010 mm

- Transport width approx.

- 3’000 mm

- Transport weight of basic plant approx.

- 42’500 kg

- Transport weight max. configuration approx.

- 49’000 kg

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.

_EVO2_Teaser_HI_Video_ENGB.jpg)

_EVO2_Teaser_LO_Video_ENGB.jpg)