MC 120i PRO Mobile jaw crusher

E-DRIVE (Diesel-electric)

43 in x 27 in x 16 in

717

US t/hr

Properties

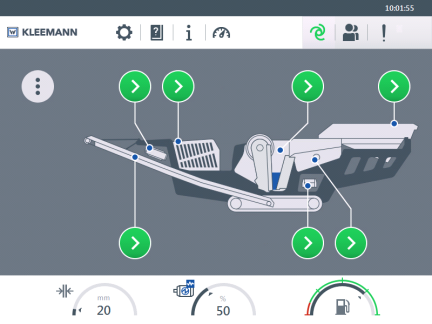

The MOBICAT MC 120i PRO, the first jaw crusher in the PRO range, is used for precrushing almost all types of natural stone. The jaw crusher is extremely robust and impresses with its low-maintenance operation. The machine therefore guarantees high production outputs.

Show more Highlights

The jaw crusher MOBICAT MC 120 PRO is extremely robust and impresses with its low-maintenance operation. The machine also guarantees high production outputs.

Technical specifications

- Max. feed size

- Feed height

- Feed height with extension

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 43 in x 27 in x 16 in

- Feed height

- 16 ft 2 in

- Feed height with extension

- 17 ft 4 in

- Hopper width

- 9 ft 4 in

- Hopper width with extension

- 12 ft 10 in

- Hopper length

- 13 ft 5 in

- Hopper length with extension

- 12 ft 10 in

- Hopper volume

- 12.7 yd³

- Hopper volume with extension

- 17 yd³

- Width x length

-

- Width x length

- 44 in x 11 ft 10 in

- Width x length

- Type

-

- Width x length

- 3 ft 12 in x 9 ft 6 in

- Type

- Double-deck heavy-piece screen

- Discharge height

- Width

- Length

-

- Discharge height

- 11 ft 4 in

- Width

- 26 in

- Length

- 21 ft 10 in

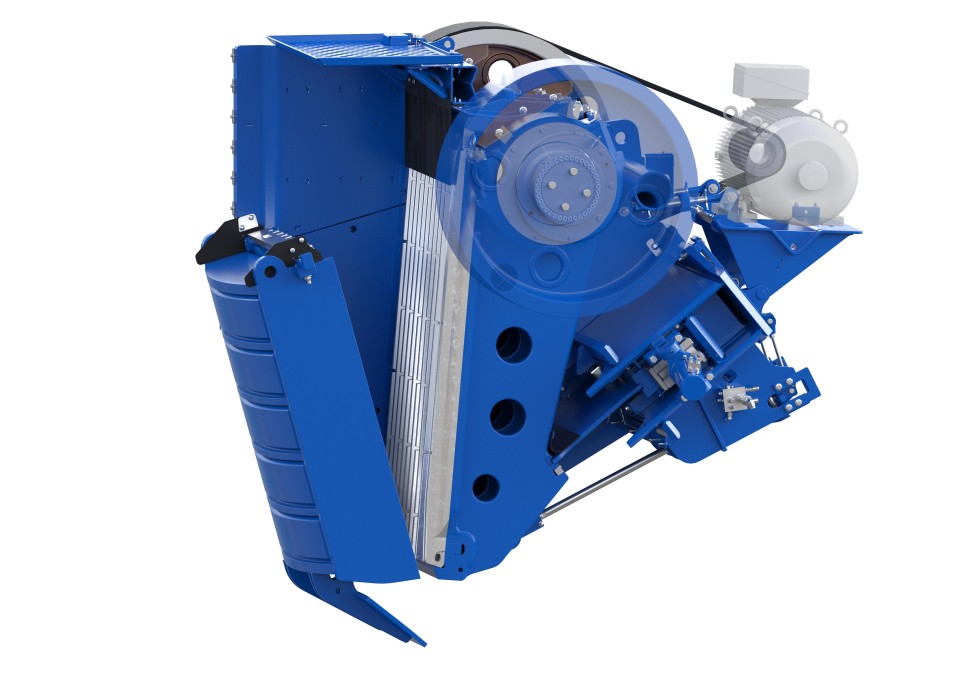

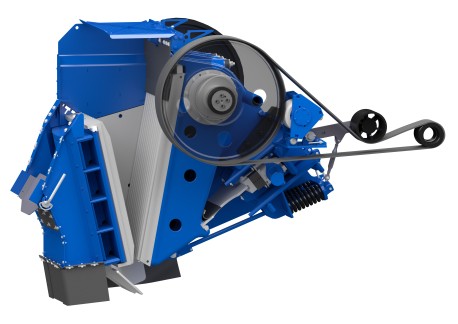

- Crusher drive type

- Crusher inlet width

- Crusher weight (approx.)

- Crusher capacity

- Single toggle jaw crusher type

- Crusher gap adjustment

- Gap width max.

- Gap width min.

-

- Crusher drive type

- electric

- Crusher inlet width

- 48 in

- Crusher weight (approx.)

- 64,350 lbs

- Crusher capacity

- 268 hp

- Single toggle jaw crusher type

- STR120

- Crusher gap adjustment

- Fully hydraulic

- Gap width max.

- 8 in

- Gap width min.

- 3 in

- Crushing capacity with CSS = 3.9" up to approx.

- Crushing capacity with CSS = 5.1" up to approx.

- Crushing capacity with CSS = 6.1" up to approx.

-

- Crushing capacity with CSS = 3.9" up to approx.

- 276 US t/hr

- Crushing capacity with CSS = 5.1" up to approx.

- 358 US t/hr

- Crushing capacity with CSS = 6.1" up to approx.

- 441 US t/hr

- Discharge height approx.

- Discharge height, extended, approx.

- Width

- Crusher discharge conveyor length

- Length, extended

-

- Discharge height approx.

- 13 ft 1 in

- Discharge height, extended, approx.

- 14 ft 11 in

- Width

- 48 in

- Crusher discharge conveyor length

- 40 ft 4 in

- Length, extended

- 45 ft 7 in

- Width x length

-

- Width x length

- 51 in x 6 ft 7 in

- Drive concept

- Generator

- Power pack manufacturer

- Power supply unit output

- Rated speed

-

- Drive concept

- E-DRIVE (Diesel-electric)

- Generator

- 500 kVA

- Power pack manufacturer

- Scania

- Power supply unit output

- 493 hp

- Rated speed

- 1,800 rpm

- Transport height approx. (standard value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant

- Transport weight max. configuration approx.

-

- Transport height approx. (standard value)

- 13 ft 5 in

- Transport length approx.

- 63 ft 6 in

- Transport width approx.

- 9 ft 10 in

- Transport weight of basic plant

- 159,900 lbs

- Transport weight max. configuration approx.

- 189,500 lbs

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.

_PRO_Highlights_LO_Video_ENGB.jpg)

_PRO_Naturstein_Polen_1.jpg)

_PRO_Naturstein_Polen_2.jpg)