A world first – BENNINGHOVEN TBA asphalt mixing plant available with hot-gas generator for the first time

28

Jan

'19

Leading recycling technology from BENNIGHOVEN – recycling drum using counterflow action with hot-gas generator now also installed on the TBA.

The TBA transportable asphalt mixing plant covers the performance ranges 160–320 t/h and is suitable for semi-mobile and stationary use. The design of the main components in container format with plug-in wiring allows for ideal transport options and reduced set-up times for the modular system. The high level of flexibility, available options, recycling feed systems and continuous retrofitting options for the components turn the TBA into an impressive all-rounder.

The large storage capacities on the hot bin section and mixed material loading silo offer real added value. The intermediate storage of the dried, heated and sorted virgin mineral is available in capacities of 60 t, 80 t and 130 t in 5, 6 or 7 bins. There is still the possibility of combining or separating sand and bypass, discharging oversize aggregate outside or collecting it in the final bin.

An integrated mixed material loading silo in dimensions of 42 to 517 t ensures a sufficient buffer whilst also providing storage capacity for up to seven asphalt types (recipes). Thanks to the modular system, this can be expanded or retrofitted at any time.

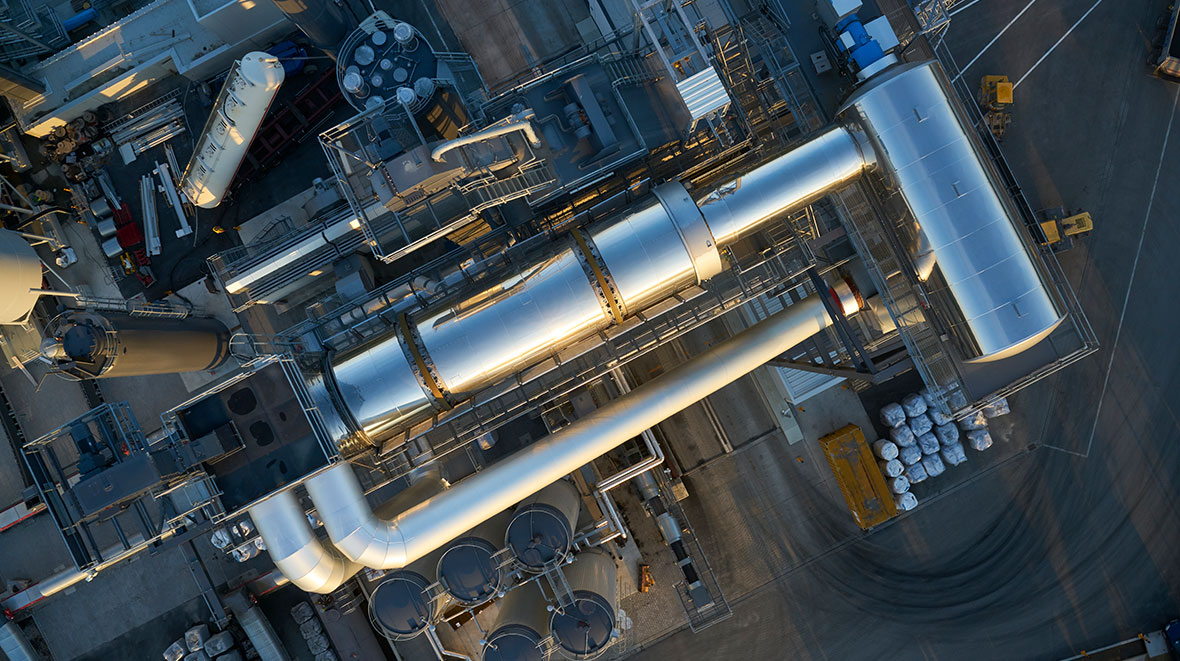

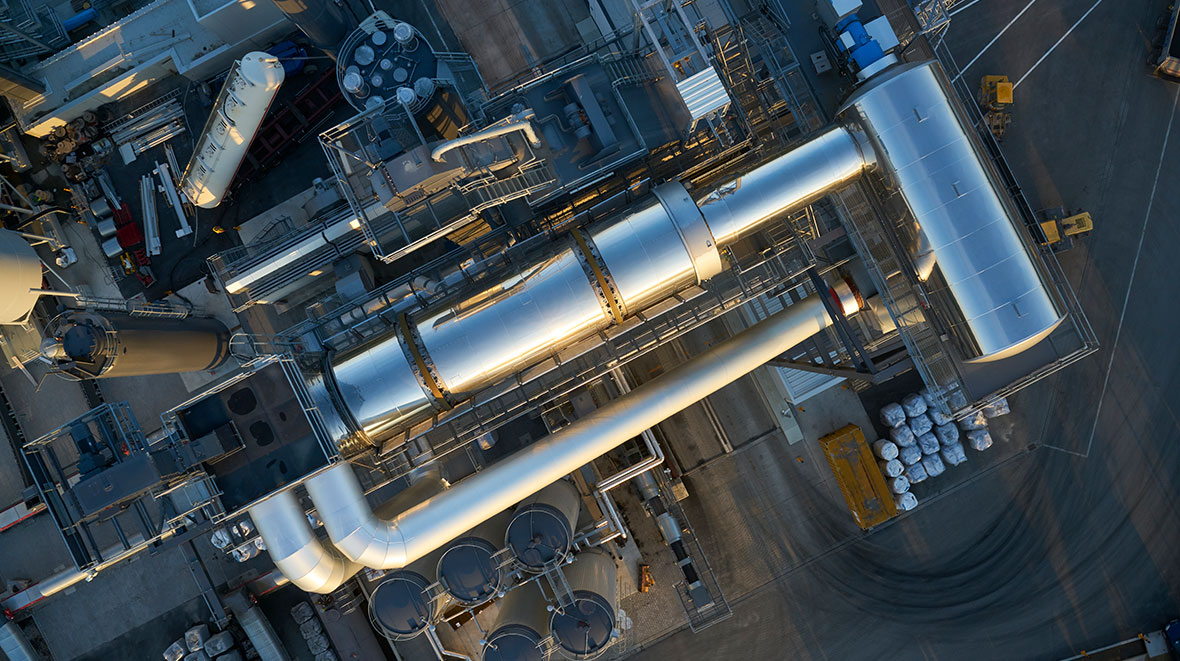

Plant with a 4 t mixer, a mixing capacity of up to 320 t/h and a loading silo of 194 t.

Plant with a 4 t mixer, a mixing capacity of up to 320 t/h and a loading silo of 194 t.

2 t, 3 t or 4 t asphalt – every 45 seconds

The TBA 2000, 3000 and 4000 have a 2000, 3000 or 4000 kg mixer and ensure a mixing capacity of 160, 240 or 320 t/h. The systems of this type are particularly robust in structure. This enables the system to be installed even in earthquake zones and to withstand strong wind loads. However, every TBA can be easily transported and quickly erected in another location due to its modularity and pre-wiring.

Highlights of transportable BENNINGHOVEN system (TBA)

• Modular system

• Wide performance range

• RAP system over 80 %

• Large variety of options

• Rugged design, therefore resistant to earthquakes and strong wind load

• Easy transportability and short set-up time due to the design of the main components in container format with plug-in wiring (“Plug & Work”)

• Storage capacity of loading silo up to 517 t

Transportable asphalt mixing plant type TBA.

Transportable asphalt mixing plant type TBA.

Leading BENNINGHOVEN recycling technologies

The mixing of recycled asphalt is a top priority when it comes to conserving natural resources. This is just one of many important reasons for the re-use of asphalt – national legislation, the reduction of emissions and increased cost efficiency are also key arguments for utilising the green technology from BENNINGHOVEN. The following technologies can be integrated in TBA plants:

• Cold recycling feed systems:

Mixer feed – for recycling quotas of up to 30 %

Multi-variable feed – for recycling quotas of up to 40 %

• Hot recycling feed systems:

Parallel drum – for recycling quotas of up to 70 %

New: Recycling drum using counterflow action with hot-gas generator – for recycling quotas of up to 80 %

• Combination of hot and cold feed systems:

The use of hot feed systems pays off in particular for large quantities and for high recycling feed quotas of up to 80 %. An additionally installed cold feed system with a possible feed quota of up to 40 % gives the customer the necessary flexibility. The cold feed system can be used for processing small quantities of up to 2 t, while the hot feed system is used for processing large orders.

Transportable asphalt mixing plant type TBA.

Transportable asphalt mixing plant type TBA.

Proven system from the major BA RPP series now also available on the TBA series

In hot recycling, the challenge is to heat the recycling material to the optimum application temperature of 160 °C while keeping emissions in the standard range and not burning the contained bitumen – especially as ever stricter standards and limit values will apply in future.

BENNINGHOVEN has the answer to this apparent conflict of interests with the hot-gas generator – a solution that is environmentally friendly, future-proof and a secure investment. Here, the recycling material – in addition to the virgin mineral – is heated by an EVO JET burner. However, this takes place indirectly in a recycling drum using counterflow action. Depending on the quality of the recycled material used, even feed quantities of over 90 % are possible.

Recycling drum using counterflow action with hot-gas generator.

Recycling drum using counterflow action with hot-gas generator.

Energy-efficient, environmentally friendly mixing of recycled asphalt

Unlike conventional parallel drums used for recycling, these recycling drums use counterflow action for heating the gas indirectly. Here, the material is conveyed in the opposite direction to the heat source. As a result, the discharge temperature of 160 °C is the same as the application temperature, with the exhaust gas temperature only approximately 100 °C (though above the dew point). This procedure leads to key advantages for the operators of asphalt mixing plants. In classic recycling systems using the parallel flow principle, the temperature is limited to 130 °C by the resulting exhaust gas emissions. However, the exhaust gas temperatures physically exceed this, which leads to increased energy consumption and a greater load on the dust collection system. In order for the asphaltic mixture to reach a temperature of 160 °C, overheated virgin mineral must be conveyed.

The EVO JET burner can be supplied with different fuels as normal and supplies the thermal energy required for drying and heating the recycling materials. The generated hot air is mixed intensively with the circulating air, also using counterflow action. In doing so, the hydrocarbons (total C) in the exhaust air are almost completely eliminated.

The BENNINGHOVEN hot-gas generator thus makes an effective contribution to energy efficiency, cost efficiency and proactive environmental protection.

The burner automatically moves forwards and backwards on its chassis, depending on the operating condition. Afterwards a partitioning element moves in or out. This procedure was developed especially to prevent damage to the burner after shutting off the firing. Without this partitioning, the burner would not be protected from the chimney effect and the resulting hot air rising from the recycling drum. When the burner is restarted, the partitioning element moves out and the entire unit moves into the operating position.

The burner automatically moves forwards and backwards on its chassis, depending on the operating condition. Afterwards a partitioning element moves in or out. This procedure was developed especially to prevent damage to the burner after shutting off the firing. Without this partitioning, the burner would not be protected from the chimney effect and the resulting hot air rising from the recycling drum. When the burner is restarted, the partitioning element moves out and the entire unit moves into the operating position.

Highlights of the BENNINGHOVEN hot-gas generator:

• Economical:

The recycling feed quota can be significantly increased – depending on the quality to over 90 + X %. This offers real added value.

• Energy efficient:

Total energy required for operation of the plant is reduced.

• Environmentally friendly:

Using a hot-gas generator means that emissions are significantly below the standard range (complies with TA Luft requirements).

Press media

Please download the ZIP-archive with the press release as WORD-file and the photos in 300 dpi.

> DOWNLOAD