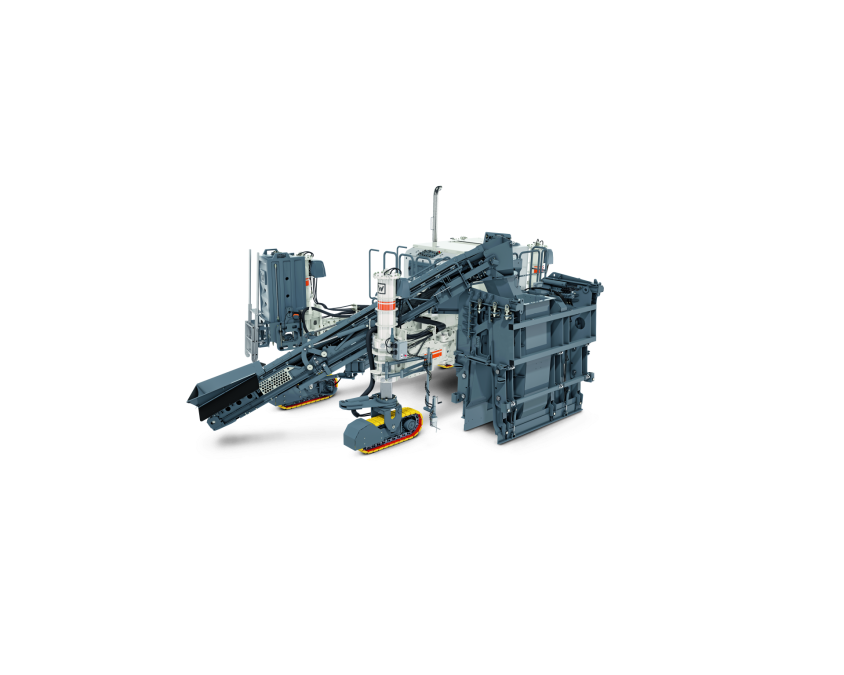

SP 61i Offset slipform pavers

EU Stage 5/US EPA Tier 4f

4 000

mm

3 000

mm

Versatile, fully modular high-performance offset slipform paver

Show less Highlights

Technical specifications

- Exhaust emissions category

- Number of track units

- Operating weight, CE

- Paving speed

- Travel speed

- Max. mould width

- Max. mould height

- Mechanical height adjustment

- Rated power

-

- Exhaust emissions category

- EU Stage 5/US EPA Tier 4f

- Number of track units

- 3

- Operating weight, CE

- 17 400 kg

- Paving speed

- 0 - 6 m/min

- Travel speed

- 0 - 21 m/min

- Max. mould width

- 4 000 mm

- Max. mould height

- 3 000 mm

- Mechanical height adjustment

- 400 mm

- Rated power

- 180 kW / 245 HP 2,100 rpm

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.