Innovations in HAMM oscillation: split drums, maintenance-free operation and VIO compaction measurement

8

Apr

'19

Over 35 years ago, HAMM became the first roller manufacturer to offer a drum with oscillation capability. Today, this technology is an integral part of HAMM’s range of products and is being continuously developed. At Bauma 2019, HAMM is presenting the latest innovation in this segment, rollers with split oscillation drums, for the first time. HAMM is also displaying a world premiere – a system for compaction measurement during oscillation compaction. These two solutions show that HAMM is responding to increasing demands in terms of the quality of compaction in earthworks and asphalt construction.

Split oscillation drums for the most exacting requirements

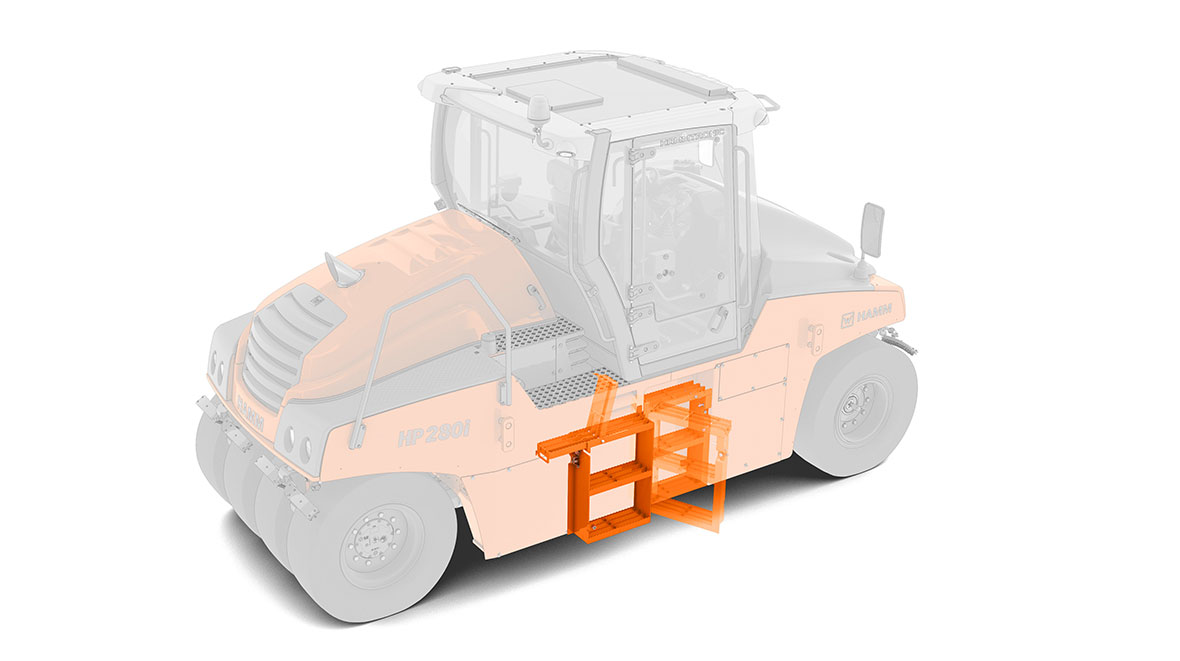

Split drums are in particular demand for the compaction of curves and roundabouts, as well as for the compaction of asphalts which are prone to displacement, such as stone mastic asphalt or polymer-modified mixes. This is because these drums prevent material displacement and cracks. HAMM has now combined this added value with the advantages of oscillation compaction and launched a split drum with oscillation onto the market.

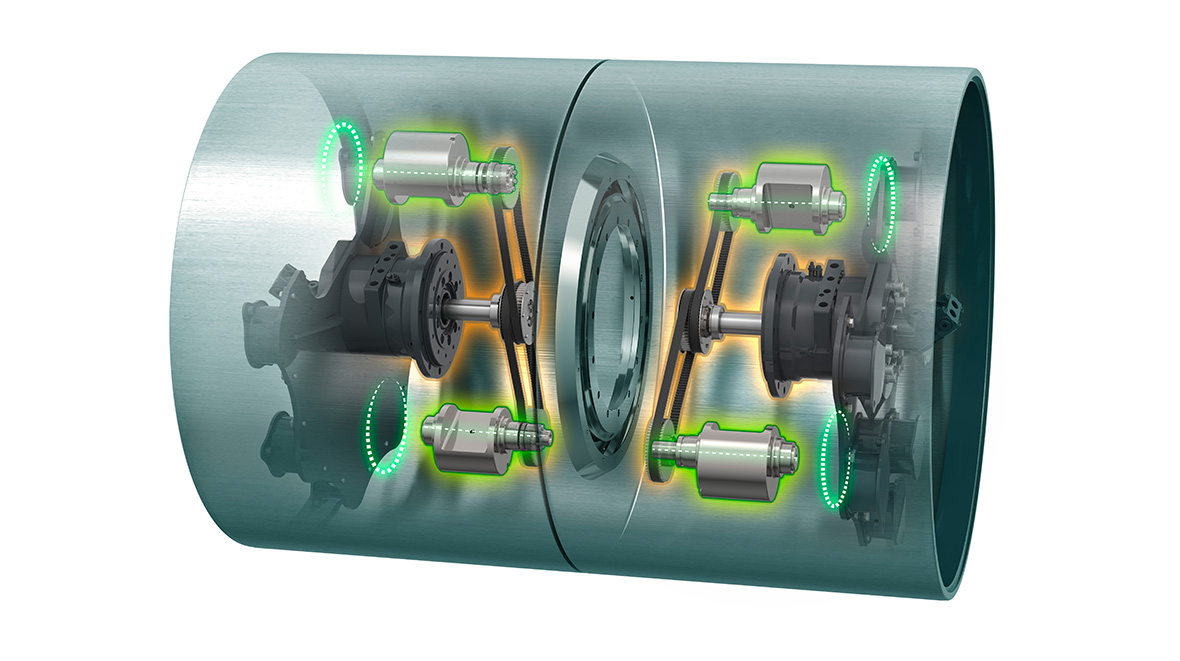

An individual, mechanically-independent oscillation unit operates in each half of the split oscillation drum. An integrated control mechanism adapts the position of the unbalance weights quickly and precisely to the position of the two drum halves. This ensures that the two drum halves always vibrate synchronously, despite their different rotation speeds around corners. The two drum halves are synchronised electrohydraulically.

The compaction specialists thus offer asphalt constructors a premium solution for challenging tasks. The split oscillating drum can be seen in the DV+ 90i VS-OS at Bauma 2019. There will also be models with a split oscillating drum available for all other rollers in the DV+ series.

Wear-resistant and maintenance-free

All HAMM oscillation drums – both non-split and the new split models – are extremely wear-resistant, as HAMM now uses an especially highly wear-resistant fine grain steel with even greater material strength for the drum shell than before. HAMM is thus significantly extending the operating life of modern oscillation drums.

In addition, all HAMM oscillation drums are now completely maintenance-free. This has been made possible by using an optimised drive concept and innovative toothed belts. It is no longer necessary to change the toothed belt after 2,000 operating hours. Drivers and the surrounding environment also benefit from this solution – the oscillation drums are now significantly quieter when in operation thanks to the new toothed belts. Furthermore, HAMM oscillation rollers no longer require oil changes – something which is still required for other systems on the market.

HAMM Compaction Meter VIO - compaction meter for oscillation

HAMM brings together a wide range of modules for compaction measurement and documentation under the term HCQ (HAMM Compaction Quality). A world first, the HAMM Compaction Meter VIO is now joining this offering. For the first time, it is now possible to measure compaction in oscillation mode. The system is already available for the H 7i VIO and H 13i VIO compactors.