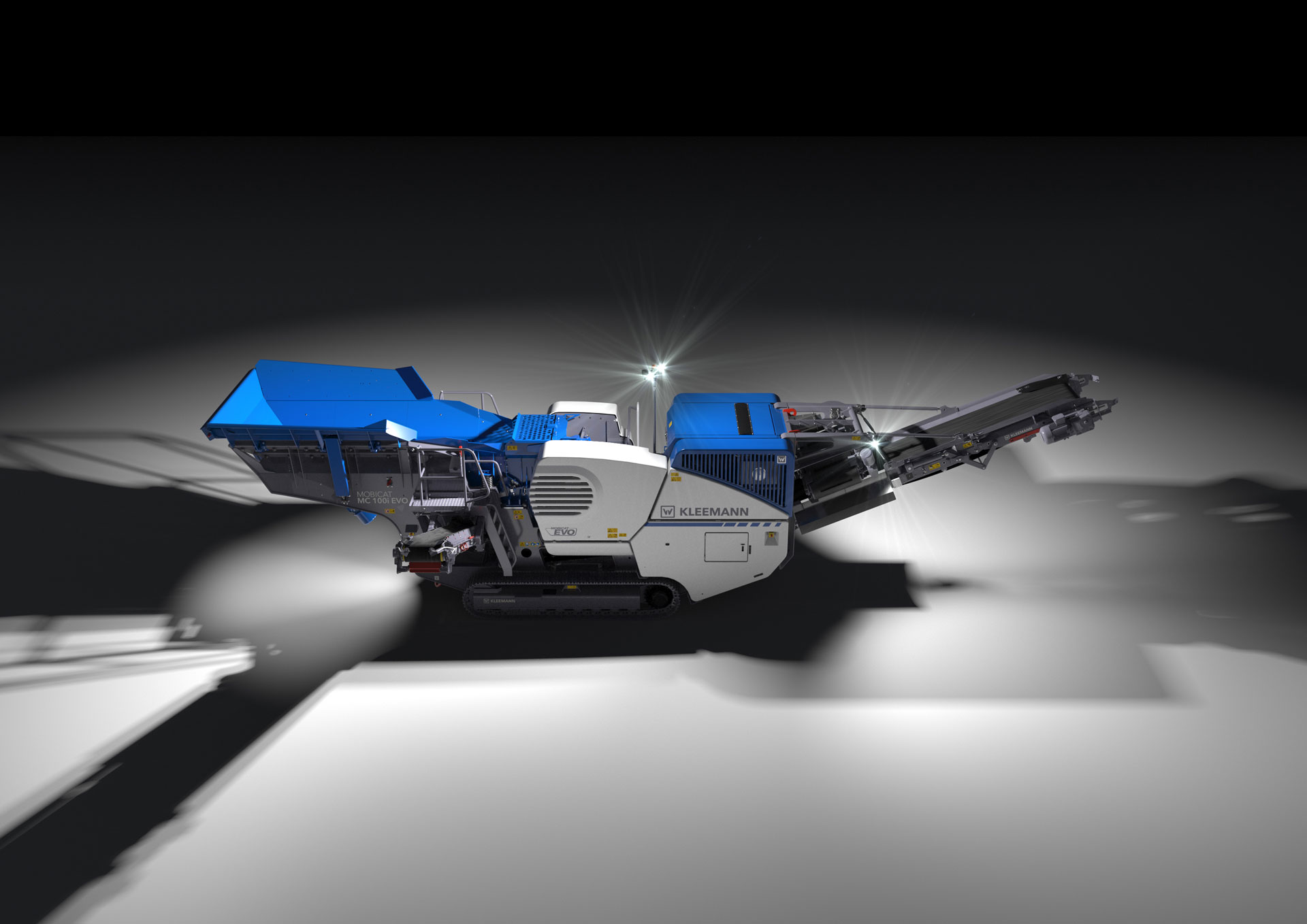

MC 100i EVO Mobile jaw crusher

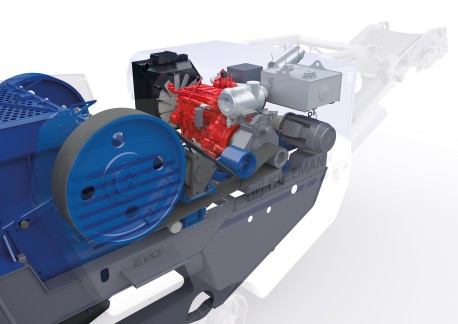

D-DRIVE (Diesel-direct)

855 mm x 530 mm x 320 mm

220

t/h

Properties

The smallest mobile jaw crusher of the EVO line impresses with its compactness and reliability. It can be used for a huge variety of materials, offering wide-ranging possibilities for both demolition companies and contract crushing companies. Thanks to diesel-direct drive, the MC 100i EVO is economical in consumption.

Highlights

Rapid deployment. Prepared for every task.

Feeding unit

CFS

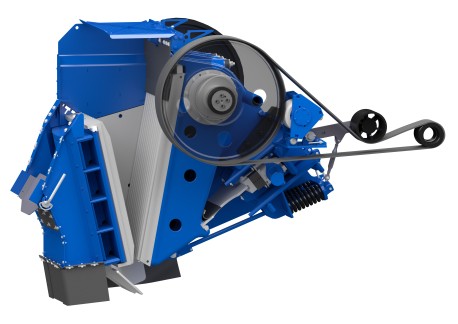

Crusher unit

Control system

Drive

Control system

Magnetic separator and crusher discharge conveyor

Transport

Safety and ergonomics

Prescreening

Technical specifications

- Max. feed size

- Feeding height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 855 mm x 530 mm x 320 mm

- Feeding height

- 3’200 mm

- Feed height with extension

- 3’720 mm

- Feed capacity up to approx.

- 220 t/h

- Hopper width

- 1’900 mm

- Hopper width with extension

- 3’100 mm

- Hopper length

- 3’000 mm

- Hopper length with extension

- 2’800 mm

- Hopper volume

- 3.2 m³

- Hopper volume with extension

- 7.1 m³

- Width x length

-

- Width x length

- 870 mm x 3,940 mm

- Discharge height

- Discharge height, extended

- Width

- Length

- Length, extended

-

- Discharge height

- 2’110 mm

- Discharge height, extended

- 3’000 mm

- Width

- 500 mm

- Length

- 2’700 mm

- Length, extended

- 5’000 mm

- Crusher drive type

- Crusher inlet (W x D)

- Crusher weight (approx.)

- Crushing power

- Single toggle jaw crusher model

- Gap setting

- Adjustment range of gap width

-

- Crusher drive type

- Direct

- Crusher inlet (W x D)

- 950 mm x 550 mm

- Crusher weight (approx.)

- 12’000 kg

- Crushing power

- 160 kW

- Single toggle jaw crusher model

- STR95-055

- Gap setting

- Fully hydraulic

- Adjustment range of gap width

- 20 mm - 130 mm

- Crushing capacity CSS = 60 mm up to approx.

- Crushing capacity CSS = 85 mm up to approx.

-

- Crushing capacity CSS = 60 mm up to approx.

- 105 t/h

- Crushing capacity CSS = 85 mm up to approx.

- 150 t/h

- Discharge height approx.

- Discharge height, extended approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 3’050 mm

- Discharge height, extended approx.

- 3’660 mm

- Width

- 1’000 mm

- Length

- 8’600 mm

- Length, extended

- 10’100 mm

- Drive concept

- Generator

- Power pack manufacturer

- Power supply unit output

- Rated speed

-

- Drive concept

- D-DRIVE (Diesel-direct)

- Generator

- 85 kVA

- Power pack manufacturer

- Deutz

- Power supply unit output

- 155 kW

- Rated speed

- 1’500 U/min

- Transport height approx. (default value)

- Transport length approx.

- Transport width approx.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

-

- Transport height approx. (default value)

- 3’200 mm

- Transport length approx.

- 12’965 mm

- Transport width approx.

- 3’000 mm

- Transport weight of basic plant approx.

- 31’000 kg

- Transport weight max. configuration approx.

- 38’500 kg

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.