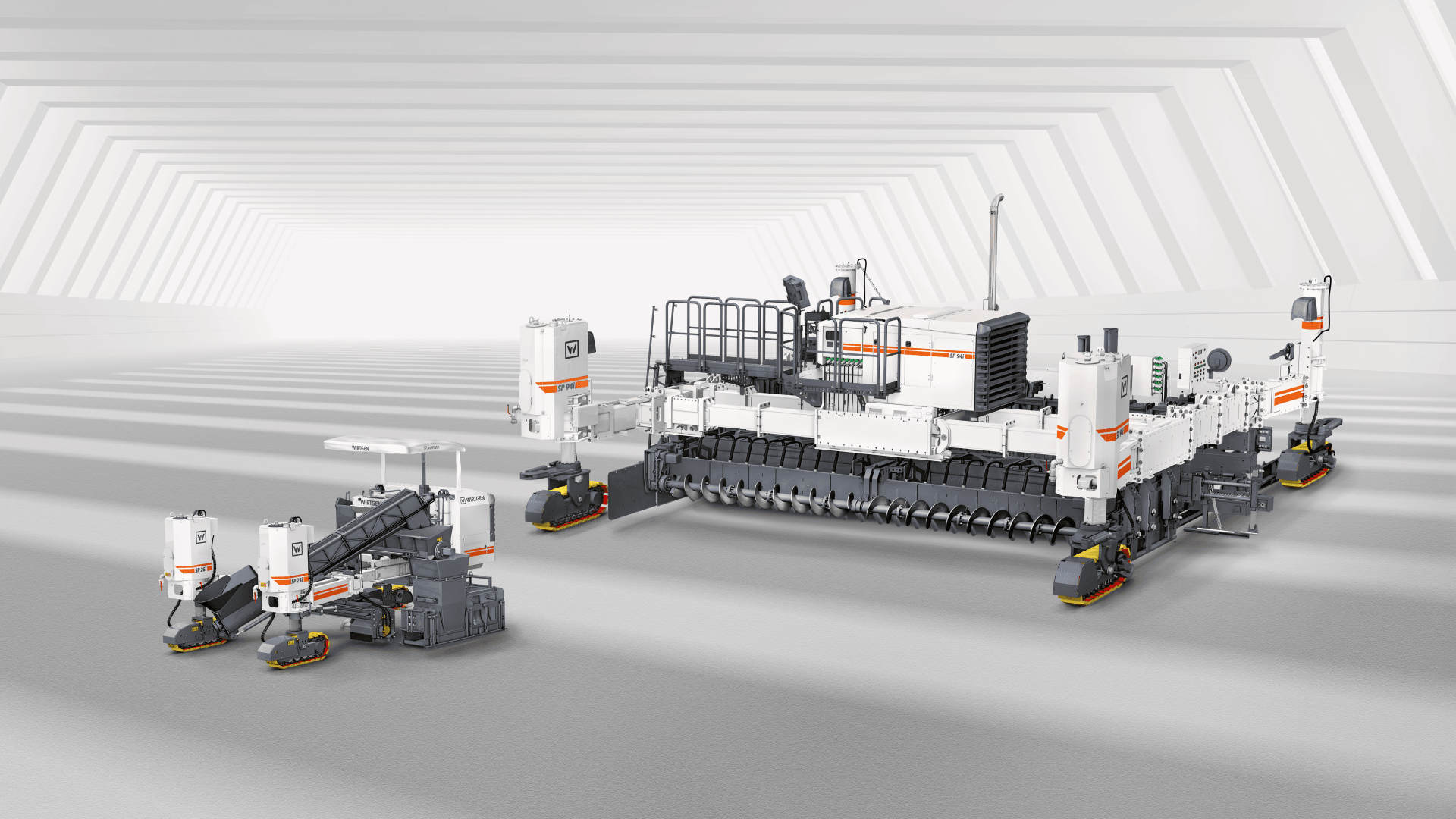

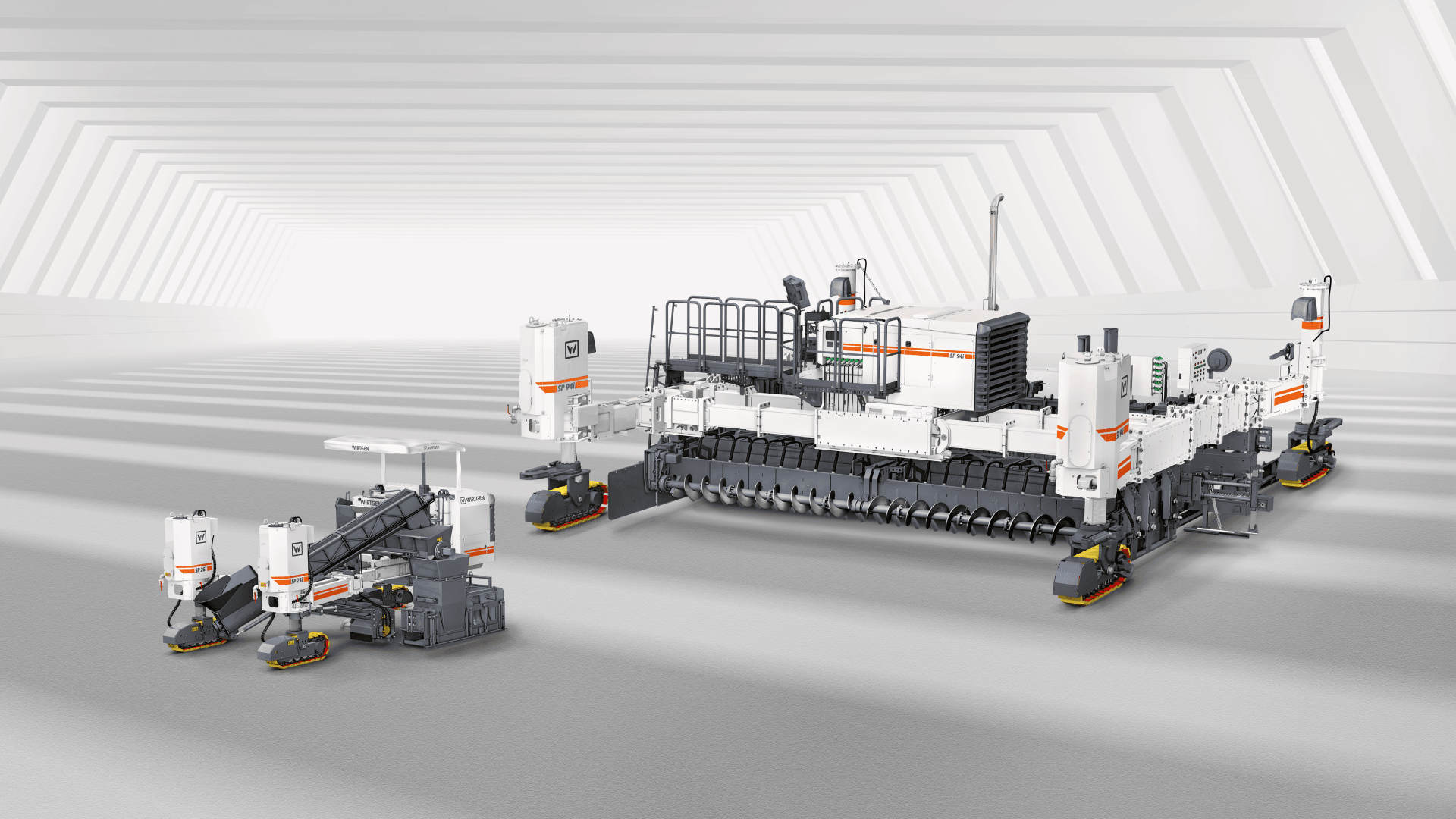

Slipform pavers

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines. In addition to single-layer concrete paving, bottom-layer and top-layer concrete can also be paved synchronously in two layers ‘wet on wet’.

Texture curing machines give the concrete pavement the desired surface texture, applying a dispersion which prevents the surface and edges from drying too quickly. The specified surface texture is achieved with a brush. Alternatively, a burlap or synthetic turf can be drawn across the concrete pavement in a longitudinal direction. Automatic crown adjustment and a film unwinder round off the features of the machine.

Texture curing machines

| Working width max. | 32 ft |

| Working height | 1 ft 8 in |

| Rated power | 55.4 kW / 74.3 hp |

| Operating weight, CE | 17,196 - 25,574 lbs |

Texture curing machines

| Working width max. | 59 ft |

| Working height | 1 ft 8 in |

| Rated power | 55.4 kW / 74.3 hp |

| Operating weight, CE | 20,062 - 40,565 lbs |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.