The WIRTGEN GROUP at

Bauma 2025

Discover how the in-depth expertise and experience of the Wirtgen Group in the construction industry can significantly improve the efficiency of your projects and generate convincing added value. With us at your side, your road to the future will be smarter, safer and more sustainable.

Visit us in Munich!

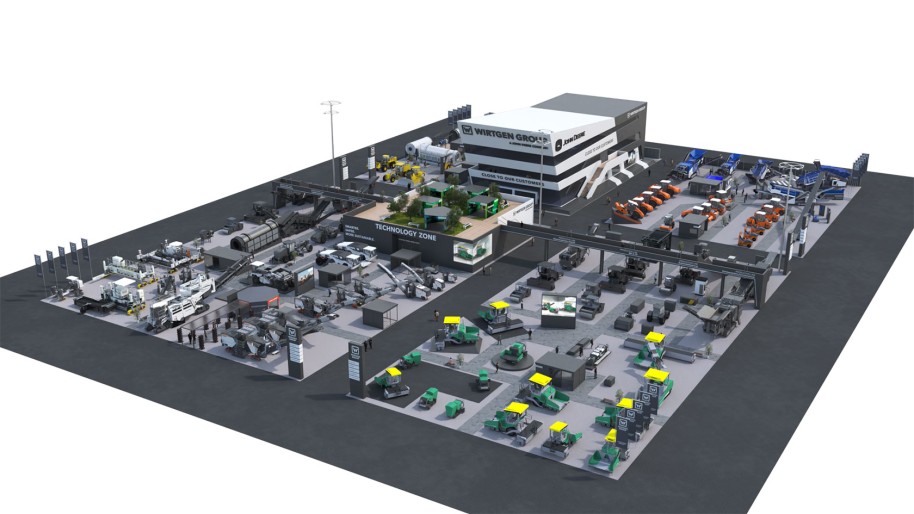

From 7 to 13 April 2025, you will have the opportunity to experience ideal solutions for your specific needs from Wirtgen, Vögele, Hamm, Kleemann, Benninghoven, Ciber and John Deere live at booth FS.1011 at bauma 2025.

How to Find Us at Bauma 2025:

The WIRTGEN GROUP Booth

Outdoor Area South, FS.1011

Opening hours April 7 – 13, 2025

Monday to Friday 9:30 a.m. - 6:30 p.m.

Saturday 8:30 a.m. - 6:30 p.m.

Sunday 9:30 a.m. - 4:30 p.m.

Neue Messe München

Am Messesee 2

81829 Munich | Germany

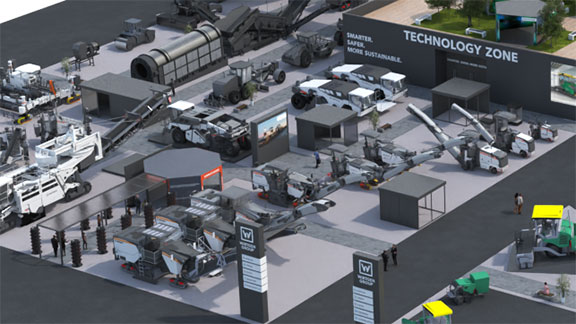

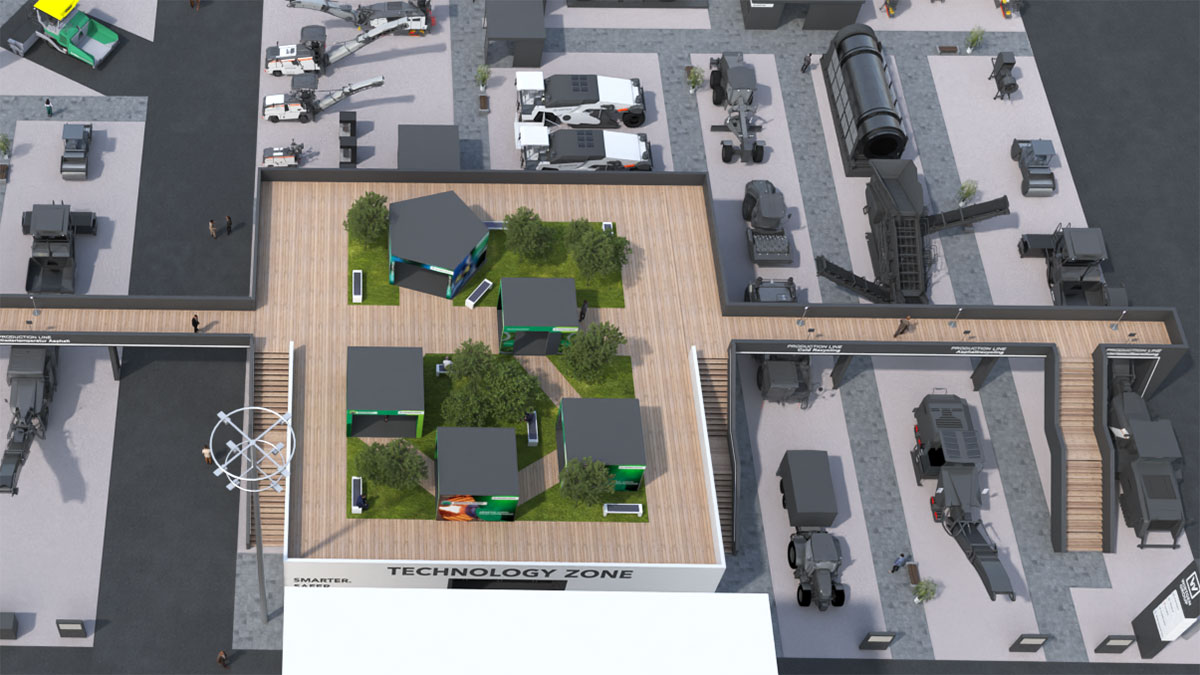

Exhibition stand overview

Enjoy an overview of our booth and plan your visit with us!

Impressions of our trade fair presentation at bauma 2025 in Munich

We would like to provide you with a unique insight into everything that happened on the WIRTGEN GROUP exhibition stand. Here you can have a look at highlights and impressions from the WIRTGEN GROUP product brands and John Deere together at Bauma 2025.

Visit our Live Shows

Fascinating insights into cutting-edge industry solutions

For the first time in its bauma history, the Wirtgen Group will present Live Shows featuring products from all the group’s brands at booth FS.1011.

Live Shows in English: Monday, Wednesday, Friday

Live Shows in German: Tuesday, Thursday, Saturday, Sunday

Plan your visit to the fair now - it's well worth a visit!

Construction in Progress at the Wirtgen Group Booth

Groundbreaking ceremony at the exhibition center in Munich: Follow the exciting construction of our approximately 13,000 square meter exhibition stand from the laying of the foundation stone to completion.

WIRTGEN GROUP Innovations

At this year’s Bauma in Munich, we will be showcasing a whole range of world premieres and innovations. You can read more about them all in our regular press releases.

Our press releases for BaumaBauma and World Premieres

Discover the numerous world premieres from the WIRTGEN GROUP at Bauma 2025

Tracked paver Mini Class

| Basic width | 1.4 m |

| Pave width, max. | 3.5 m |

| Maximum laydown rate | 300 t/h |

Wheeled paver Compact Class

| Basic width | 1.85 m |

| Pave width, max. | 4.5 m |

| Maximum laydown rate | 250 t/h |

Tracked paver Universal Class

| Basic width | 2.55 m |

| Pave width, max. | 10 m |

| Maximum laydown rate | 1,000 t/h |

Tracked paver Universal Class

| Basic width | 2.55 m |

| Pave width, max. | 10 m |

| Maximum laydown rate | 700 t/h |

Wheeled paver Universal Class

| Basic width | 2.55 m |

| Pave width, max. | 8 m |

| Maximum laydown rate | 700 t/h |

PowerFeeder

| Conveying system capacity (up to) | 1,200 t/h |

| Weight | 19,765 kg |

| Transport width | 3 m |

| Conveying system capacity (up to) | 1,200 t/h |

| Weight | 24,285 kg |

| Transport width | 3 m |

Compactor with smooth drum

| Weight | 11,815 kg |

| Drum width | 2,140 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

_NEO(e)_general_view_Photo_0001.png)

Mobile impact crusher

| Drive concept | D-DRIVE (Diesel-direct) |

| Max. feed size | 500 mm x 800 mm x 300 mm |

| Feed capacity up to approx. | 250 t/h |

_NEO(e)_EPower_general_view_Photo_0001.png)

Mobile impact crusher

| Drive concept | E-DRIVE (Diesel-electric) |

| Max. feed size | 500 mm x 800 mm x 300 mm |

| Feed capacity up to approx. | 250 t/h |

Mobile scalping screen plant

| Drive concept | H-DRIVE (Diesel-hydraulic) |

| Max. feed size | 640 mm x 400 mm x 240 mm |

| Feed capacity up to approx. | 350 t/h |

Mobile scalping screen plant

| Drive concept | H-DRIVE (Diesel-hydraulic) |

| Max. feed size | 880 mm x 550 mm x 330 mm |

| Feed capacity up to approx. | 750 t/h |

Exhibits at Bauma 2025

Click through the WIRTGEN GROUP product portfolio and learn more about our product brands and their innovations:

Laboratory foamed bitumen plant

| Bitumen temperature | 140 - 200°C |

| Air pressure | 0 - 10 bar |

| Water content of bitumen | 0 - 5 % |

Laboratory mixer

| Mixing capacity | 30 kg |

| Mixer type | Twin-shaft pugmill |

Laboratory compactor

| Impact energy, max. | 23 J |

Tractor-towed stabiliser

| Working width max. | 2,500 mm |

| Working depth | 500 mm |

| Recommended engine power | 250 kW / 340 HP |

Offset slipform pavers

Highway Class tracked paver

| Basic width | 2.55 m |

| Pave width, max. | 11.5 m |

| Maximum laydown rate | 900 t/h |

Tracked paver Highway Class

| Basic width | 2.55 m |

| Pave width, max. | 14 m |

| Maximum laydown rate | 1,100 t/h |

Extending screed

| Compacting systems | TV, TP1, TP2, TP2 Plus |

| Pave width | 2.55 m - 8.75 m |

| Basic width | 2.55 m |

Pneumatic-tyre roller

| Weight | 9,480 kg |

| Drum width | 1,830 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

| Drive concept | D-DRIVE (Diesel-direct) |

| Max. feed size | 990 mm x 620 mm x 370 mm |

| Feed capacity up to approx. | 400 t/h |

Mobile cone crusher

| Drive concept | D-DRIVE (Diesel-direct) |

| Max. feed size | 200 mm |

| Feed capacity up to approx. | 270 t/h |

_EVO2_Masked_Image.png)

Mobile impact crusher

| Drive concept | D-DRIVE (Diesel-direct) |

| Max. feed size | 1,040 mm x 650 mm x 390 mm |

| Feed capacity up to approx. | 450 t/h |

Mobile scalping screen plant

| Drive concept | H-DRIVE (Diesel-hydraulic) |

| Max. feed size | 800 mm x 500 mm x 300 mm |

| Feed capacity up to approx. | 500 t/h |

_EVO_Masked_Image.png)

Mobile classifying screen

| Drive concept | H-DRIVE (Diesel-hydraulic) |

| Max. feed size | 160 mm x 100 mm x 60 mm |

| Feed capacity up to approx. | 500 t/h |

Track-mounted stacker

| Discharge height | 10,100 mm |

| Feed capacity up to approx. | 450 t/h |

| Stockpile volume | 1,350 m³ |

Whether a Benninghoven or third-party plant, with a BENNINGHOVEN Retrofit you can remain or get back to state of the art.